Description

Soldering and Welding Machine SW

Apparatus for gas-flame work in industry, car repair, refrigeration and air-conditioning equipment, jewelry, dentistry, etc.

See next videos:

HHO devices are widely used for cutting, welding and soldering of metals, glass and ceramics. Their advantage is that it is not necessary to use bottles with acetylene or propane-butane and oxygen. Consumables are only pure distilled water and hydrocarbons. The hydrogen-oxygen gas mixture never runs out and thus the person working with the device is not limited in his work by the amount of gas to be able to make the required amount of welding.

“HHOFrance-WS” is a powerful device that is designed for cutting and welding metals up to 6 mm. It is designed for work in industrial car repair shops. The device is very convenient for layering and soldering of non-ferrous and ferrous metals. The flame temperature is regulated in the range from 600 to 2800 degrees. The device makes very good solders of copper pipes in the production and repair of refrigeration and cooling equipment. It is suitable for repairing radiators, engine blocks and chassis. The device is extremely suitable for soldering in the manufacture of electric motors and transformers.

Another model of the device is “HHOFrance-WS900”. It is designed to perform gas-flame work in places where there is only a single-phase power supply. The device allows welding of pipes with a wall thickness of up to 5 mm, welding of cast iron and non-ferrous metal details. With this device, metals up to 30 mm thick can be cut. In this case, the heating flame is made by the electrolysis apparatus and additional cutting oxygen is supplied. When applying this technology, an extremely smooth cut is obtained and no deposits and slags are formed.

Hydrogen gas cutting and welding machines can be used when working underground in underground garages and warehouses, tunnels and shafts as they are extremely safe to use, unlike the use of propane or acetylene cylinders.

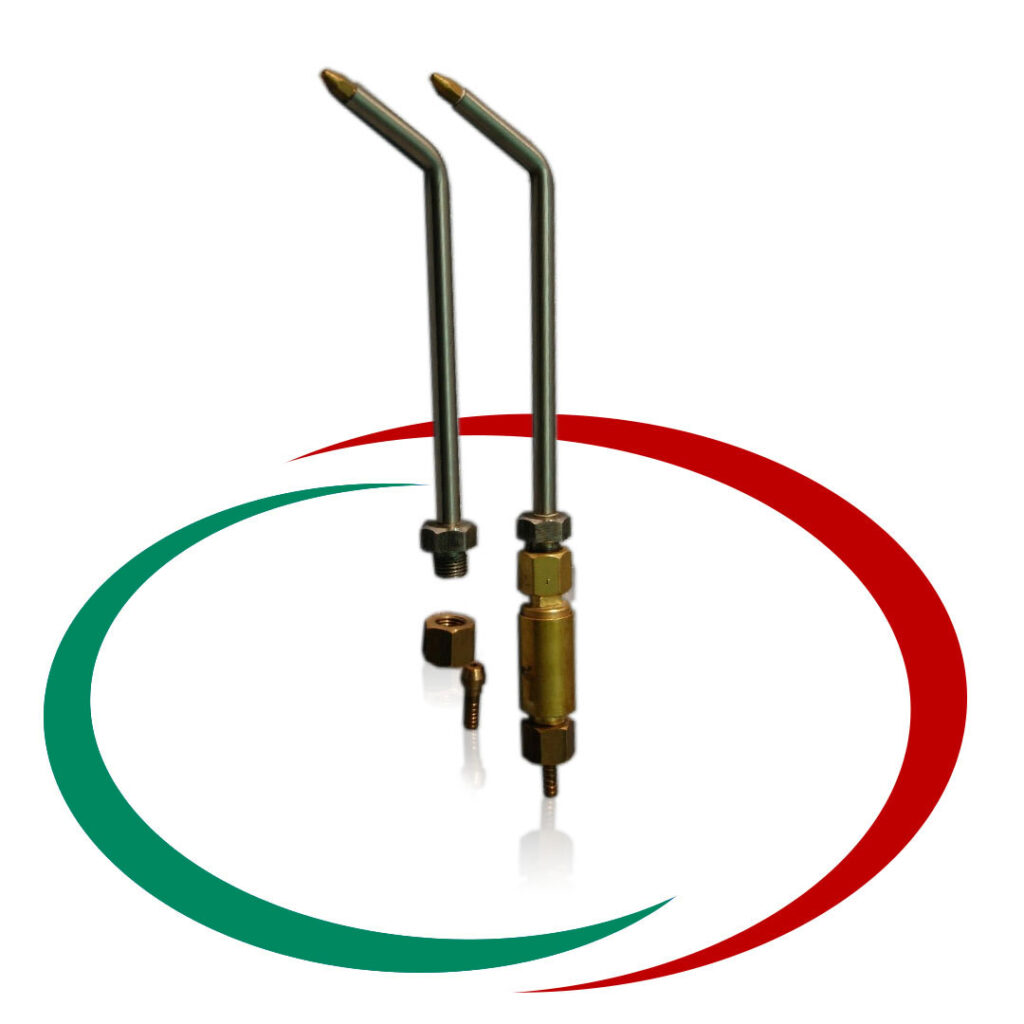

Equipment:

- HHO production 10 litres per minute max, adjustable

- Electrolyte tank capacity 15 litres

- Max water consumption 150 ml per hour

- Made in France

- Size 95 X 48 X 54 cm

- Weight 70 kg empty / 87 kg fully charged

- Power 230 Vac

- Power consumption 1,8 kW max

Functionality:

- Working pressure adjustment module

- Start

- Stop

- HHO production rate

- Cell pressure transducer and sensore

- Temperature control

- Alarms and warning indicators

- Auto OFF

- Electrolyte quality control

Safety:

- Electrolyte low level warning (light and audio)

- Electrolyte low level safety shut down

- Special cooling instalation

- Pressure ant temperature stop safety shutdown

- Fire arrestor in line

- Cell fully tested for explosion containment

Service:

- Lifetime warranty

- Lifetime supply of consumables (Subject to contract)

- Future functionality – secure remote access (not offered in this configuration)