Description

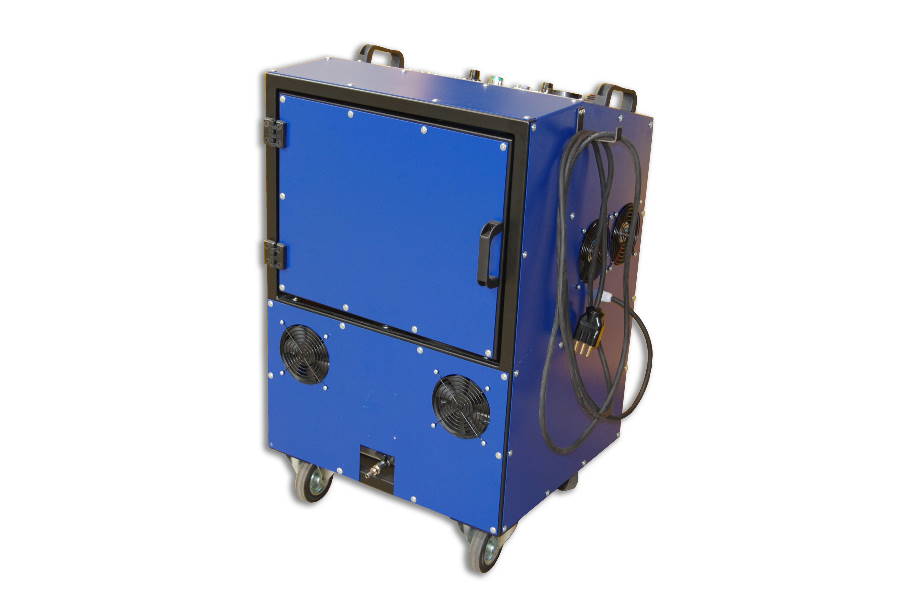

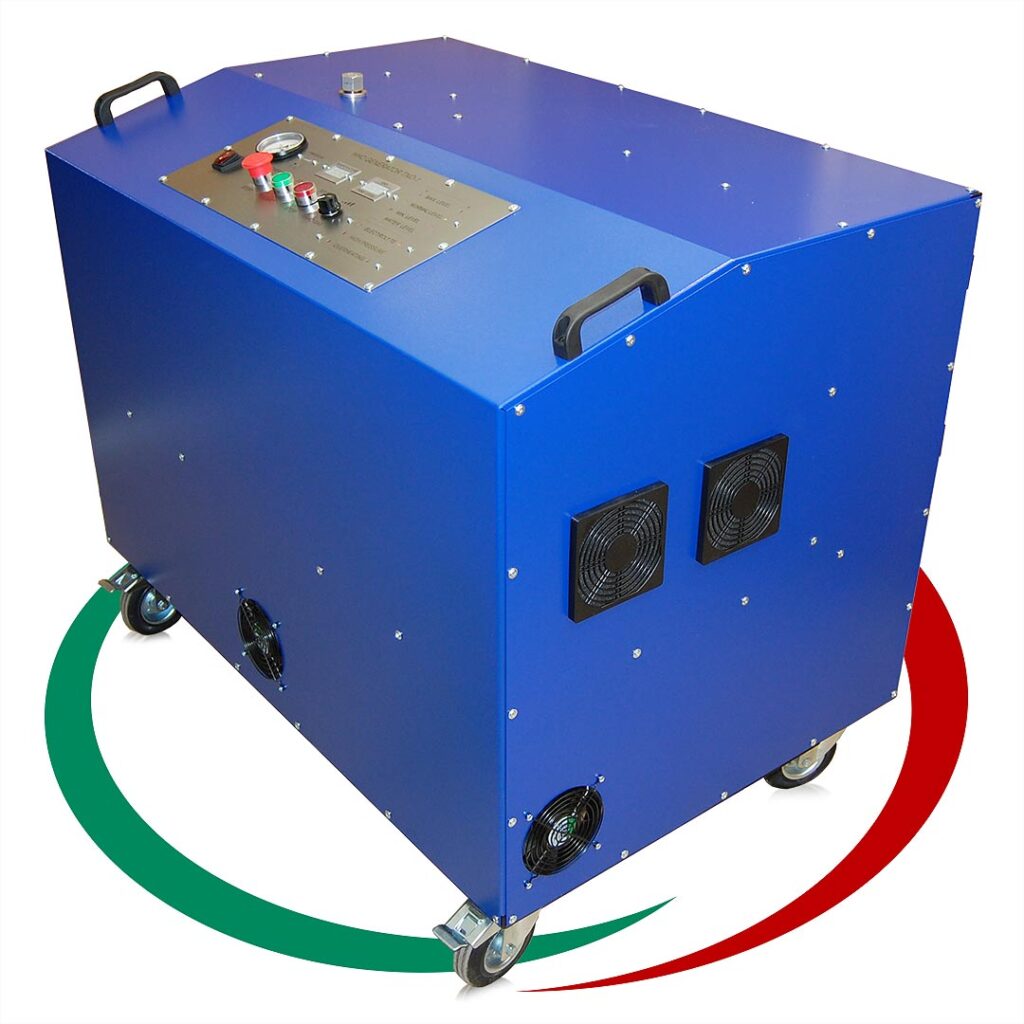

Carbon Cleaning Machine

HHO Bulgaria CC10

Equipment :

- HHO production 10 liters per minute max, adjustable

- 25 liter tank capacity electrolyte

- Max water consumption 300 ml per hour

- Made in France

- Size 95 X 54 X 48 cm

- Weight 70 kg empty / 95 kg fully charged

- Power 230 Vac

- Power consumption 1.8 kW max

Functionality:

- Start

- Stop

- HHO production rate

- Cell pressure

- Timer 0-99 minutes

- Alarms and warning indicators

- Auto OFF

- Quality control electrolyte

Safety:

- Low level warning electrolyte (light and audio)

- Low level safety shut down electrolyte

- Motor turning indicator

- Motor stop safety shutdown

- Fire arrestor in line

- Cell fully tested for explosion containment

Service:

- Lifetime warranty

- Lifetime supply of consumables (Subject to contract)

- Future functionality – secure remote access (not offered in this configuration)

What physical or chemical

phenomenon is the basis of

carbon-cleaning with hydrogenoxygen

gas (HHO)?

Context

HHO carbon-cleaning is the process of removing carbon deposits from the internals

of the combustion engine and the exhaust tract – DPF, EGR valve, Catalyst, etc. – by

means of adding a mixture of gaseous Hydrogen and Oxygen (HHO gas) into the

engine air-intake manifold.

The goal of HHO carbon-cleaning is reducing the negative impact of carbon deposits

formation in the engine, in order to reduce harmful exhaust emissions, lower

maintenance cost, and improve fuel efficiency.

Process

The basis of carbon-cleaning of carbon deposits in a combustion engine by HHO

gas, such treatment being primarily applied to the diesel engines, is the chemical

reaction between Carbon and Hydrogen and Oxygen, at elevated pressure and

What physical or chemical phenomenon is the basis of carbon-cleaning with hydrogen-oxygen gas (HHO)? 2

temperature, facilitated by the presence of traces of Nickel and Cobalt, found in

combustion engine block components, as catalysts.

From R. F. Baddour and J. M. Iwasyk:

Reaction of Carbon with Hydrogen and

Oxygen

The chemical reactions between Carbon (C) in solid form, and Hydrogen (H2) and

Oxygen (O2) in active gaseous forms, are:

C + 2H2 → CH4

C + O2 → CO2 (for Carbon valency +4)

2C + O2 → 2CO (for Carbon valency +2)

Simultaneously, in the presence of CO2 and CO, the Sabatier reaction takes place:

CO2 + 4H2 → CH4 + 2H2O

CO + 3H2 → CH4 + H2O

From Stefan Rönsch and Jens Schneider:

Finally, the resulting Methane is combusted together with the fuel, and the resulting

CO2 and the water vapour are mixed with the exhaust gases of the combustion

engine:

CH4 + 2O2 → CO2 + 2H2O

Effectiveness

What physical or chemical phenomenon is the basis of carbon-cleaning with hydrogen-oxygen gas (HHO)? 3

The effectiveness of the carbon-cleaning process can be verified by measuring two

types of parameters:

Short-term parameters – measured immediately after the procedure;

Long-term parameters – measured during weeks or months after the procedure;

Some of the short-term parameters, related to the level of effectiveness of the

process of HHO carbon-cleaning:

Opacity of the exhaust gases ‘Before’ and ‘After’ the process, measured by a

standard opacimeter, in 1/m units;

DPF back-pressure ‘Before’ and ‘After’ the process, measured via an OBD-II

diagnostic tool, in Mpa units;

Airflow through DPF ‘Before’ and ‘After’ the process, measured via an OBD-II

diagnostic tool, in g/sec units;

Soot accumulation in DPF ‘Before’ and ‘After’ the process, measured via an

OBD-II diagnostic tool, in grams;

Visual inspection of engine and exhaust components ‘Before’ and ‘After’ the

process;

Some of the long-term parameters, related to the level of effectiveness of the

process of HHO carbon-cleaning:

Lower fuel consumption, measured over the same period ‘Before’ and ‘After’ the

HHO carbon-cleaning;

Lower maintenance cost, linked to reduced number of issues with DPF, EGR

valve, etc.

Further reading

The reaction of Carbon with Hydrogen at High Pressure. JD Blackwood.

https://doi.org/10.1071/CH9590014

The reaction between carbon and the products of hydrogen, oxygen and water

microwave discharges. F.J Vastola, P.L Walker Jr., J.P Wightman.

https://doi.org/10.1016/0008-6223(63)90004-6

Reaction of Hydrogen Atoms with Solid Carbon. G. M. HARRIS, A. W.

TICKNER.

What physical or chemical phenomenon is the basis of carbon-cleaning with hydrogen-oxygen gas (HHO)? 4

https://doi.org/10.1038/160871a0

Sabatier reaction

https://en.wikipedia.org/wiki/Sabatier_reaction

Review on methanation – From fundamentals to current projects. Stefan

Rönsch, Jens Schneider, et al.

https://doi:10.1016/j.fuel.2015.10.111